PINT Automatical Nesting System

PINT serials are the latest products developed by our company. It is focusing the special requeirments in skin cutting industry and some other industries. The system supports recongnizing the skin outline from the photo image taken by common home camera. It reads the standard data exchage format - AAMA files and also normal AutoCAD drawing blocks in DXF files. The user can also try to input blocks from a HP-GL file.PINT has a nesting module designed for the features of the industries which is good at both utilization ratio and calculation efficiency. User can also export the nesting task to several 3rd-part software to do calculation.

PINT supports several cutting path exportations with different CAM command formats. We'd like to cooperate with machine venders to supply the matching format with the machine. Software OEM is also available.

The features of this software system are:

Trial Application

Trial Version of PINT serials are available now. If you are interested in PINT software, please send application mail to: sun@lsccm.com

PINT Skin Version -- supports outline input basing image processing for irregular skin.

This skin version is for nesting work in irregular area of skins. It has a powerful image processing module by which user can read the irregular outline of the skins from photos. User can take these photos on the cutting machine; do nesting calculation and export to execute the cutting right away. Or user can read many skins one by one at one time and save in a file like a skin outline library. PINT has function to help the work of layout skin to match the nesting result on the cutting machine. So that user call in the skin outline from the library when needed.

The Skin Version also supports the working mode to read the skin outline on a plane board. In this mode, the cutting machine will be free from the skin reading so that the working efficient will be better. The cutting machine will use a projector to do positioning by display the the nesting result on the machine.

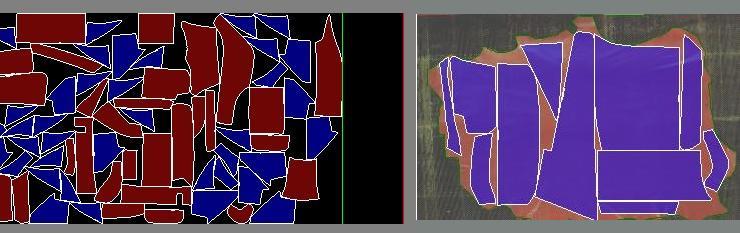

PINT Path Version -- supports calculation for some special cutting pathes of foam and other industries.

PINT Path Version has no Photo Input module. It supports nesting in segments and also the differnt path logics and CNC exporting formats for different industry. This products has been adopted by Foem cutting instrument factory. All companies are welcomed to contact us for cooperation.

PINT Print Version -- supports image layout by automatical nesting and corresponding cutting solution for printing industry.

PINT Print Version has no Photo Input module. It support read Image Block from file formats of PDF, PNG, BMP and so on. The image blocks can be used in common nesting calculation and then a correct nesting result image can be created when you do export. This image will be used to do print job. PINT Print Version supports different positioning modes when do cutting on the machine. User can select to use a projector to matching the positon. Or user can use a cutting machine which has camera to locate the positioning points which are created with the printable image.Any printing or cutting equipment companies are welcomed to contact us for cooperation.

Please download the demo package (with video and document) for this solution to understand more: 隶首印刷行业排料切割方案介绍.rar

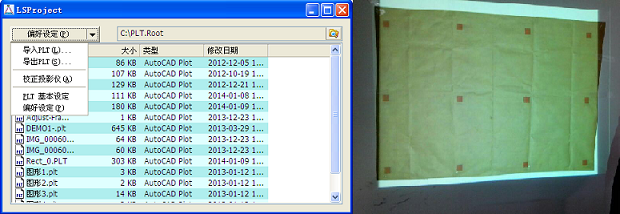

PINT Projector System For Cut-Machine -- LSProject

LSProject can be used stand alone or with PINT. LSProject supports a simple and convenient adjusting module to match the display of the projector with the dimention of the cutting machine. So that it will be feasible to layout the skin material on the correct position. And the action is also obviously to do cutting in way of WYSIWYG.

If necessary, we can supply multi-projector version to support joint-display of more than one projector. The displaying precision will be OK for a big dimention cutting machine. Also PLT data can be stretched to match the distortion of the material. This might happens in printing indurstry.Please download LSProject User Manual Book to understand more: LSProject User Manual Book.pdf

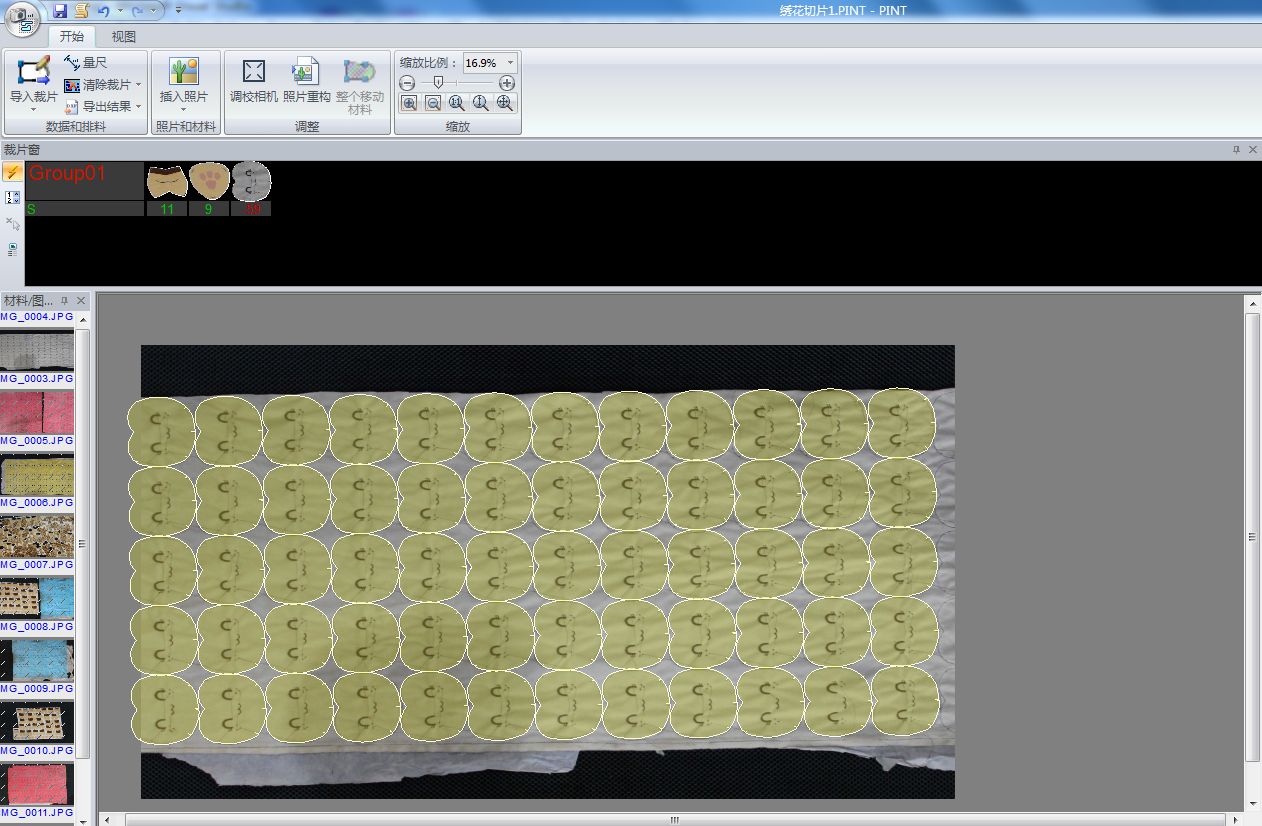

PINT Positioning System For Trade Mark and Applique -- PINT_EmbCut

PINT_EmbCut supplies a different solution for the positioning work to do cutting for trade mark or applique. By this way, the operator has the ability to check and edit the positions found by PINT before print to cutting machine so that the damaging rate will be low.

PINT_EmbCut uses civil camera to take photo of the whole cutting plane. By the core adjusting module, PINT can recover the distortion of the lens. After a processing of automatical-positioning, operator can check the result and modify even the outline to fit the image. Those are not found out can also be punched manually before print to the cutting machine.

Please download the guidance document for more information: PINT Solution For Trade Mark and Applique Cutting

XPos -- The Visial Positioning System For Cutting Machine.

The core of XPos is a set of Windows DLL. XPos positionging module supplies the vision algorithm basing civil cameras. The positionging precision is less than one pixel. The pixel size will be 0.078mm for a camera with 300K pixels (640*480) and the vision area is about 50mm width.

Currently, XPos supplied only the camera handling and positioning calculation. If required, we will supply the developing work to operate the cutting machine and to transform the PLT data like offseting, rotating and stretching.

Please download the guidance document for more information: XPos应用概要指导.pdf